Introduction: Why a Small Business CRM Demo Matters

Running a small business is a rollercoaster. One minute you’re celebrating a new client, the next you’re scrambling to keep track of leads, manage customer interactions, and juggle a million other tasks. In this fast-paced environment, it’s easy for things to fall through the cracks, leading to lost opportunities and frustrated customers. That’s where a Customer Relationship Management (CRM) system comes in. But before you commit, seeing a small business CRM demo is crucial. It’s not just about seeing pretty pictures; it’s about understanding how a CRM can become the central nervous system of your business, driving growth and efficiency.

This article will delve into the world of small business CRM demos, explaining why they’re essential, what to look for, and how to choose the right CRM for your specific needs. We’ll explore the key features you should expect to see in a demo, how to evaluate different CRM platforms, and ultimately, how to leverage a CRM to take your small business to the next level. Prepare to be amazed by the potential! This is your ultimate guide to understanding and maximizing the benefits of a CRM demo.

The Power of a CRM for Small Businesses

Before we dive into the specifics of a CRM demo, let’s understand the fundamental power of a CRM. At its core, a CRM is a software solution designed to manage and analyze customer interactions and data throughout the customer lifecycle. It helps you build stronger relationships with customers, personalize your interactions, and ultimately, drive sales. Think of it as a centralized hub for all your customer-related information, accessible to your entire team, from sales to marketing to customer service.

Here’s a breakdown of the key benefits a CRM offers to small businesses:

- Improved Customer Relationships: By centralizing customer data, a CRM allows you to understand your customers better. You can track their purchase history, preferences, and communication history, enabling you to personalize your interactions and provide exceptional customer service.

- Increased Sales: A CRM helps you manage your sales pipeline, track leads, and identify opportunities to close deals. It automates many of the tedious tasks associated with sales, freeing up your team to focus on building relationships and selling.

- Enhanced Marketing Effectiveness: CRMs integrate with marketing automation tools, allowing you to create targeted marketing campaigns based on customer data. You can segment your audience, personalize your messaging, and track the performance of your campaigns.

- Streamlined Operations: A CRM can automate many of the administrative tasks associated with customer management, such as scheduling appointments, sending follow-up emails, and generating reports. This frees up your team to focus on more strategic initiatives.

- Better Data Analysis and Reporting: CRMs provide valuable insights into your business performance. You can track key metrics, such as sales, customer satisfaction, and marketing ROI. This data allows you to make informed decisions and optimize your strategies.

In essence, a CRM empowers you to work smarter, not harder. It provides the tools you need to improve customer relationships, increase sales, and streamline your operations, all of which contribute to the long-term success of your small business. Now, let’s see how a CRM demo can show you all of this in action.

What to Expect in a Small Business CRM Demo

A CRM demo is your chance to get a hands-on look at a CRM system and see how it can work for your business. It’s not just a sales pitch; it’s an opportunity to ask questions, explore the platform’s features, and determine if it’s the right fit for your needs. A good demo will typically cover the following key areas:

1. Contact Management

This is the heart of any CRM. The demo should show you how the CRM allows you to store and manage contact information, including names, addresses, phone numbers, email addresses, and social media profiles. Look for features like:

- Contact import and export: Can you easily import your existing contact data from spreadsheets or other systems?

- Contact segmentation: Can you group contacts based on various criteria, such as demographics, purchase history, or lead source?

- Duplicate contact management: Does the CRM automatically identify and merge duplicate contacts?

- Custom fields: Can you create custom fields to store information specific to your business needs?

2. Lead Management

The demo should demonstrate how the CRM helps you capture, track, and nurture leads. Look for features like:

- Lead capture forms: Can you create web forms to capture leads from your website or landing pages?

- Lead scoring: Does the CRM automatically score leads based on their engagement and behavior?

- Lead assignment: Can you automatically assign leads to sales representatives?

- Lead nurturing workflows: Can you create automated email sequences to nurture leads and guide them through the sales funnel?

3. Sales Pipeline Management

A CRM should help you visualize and manage your sales pipeline, from lead to close. Look for features like:

- Visual pipeline: Does the CRM provide a clear and intuitive visual representation of your sales pipeline?

- Deal tracking: Can you track the progress of each deal through the pipeline?

- Task management: Can you create and assign tasks to sales representatives related to specific deals?

- Sales forecasting: Does the CRM provide sales forecasting capabilities based on your pipeline data?

4. Marketing Automation

Many CRMs offer marketing automation features to help you streamline your marketing efforts. Look for features like:

- Email marketing: Can you create and send email campaigns?

- Marketing automation workflows: Can you create automated email sequences based on customer behavior?

- Segmentation: Can you segment your audience based on various criteria?

- Reporting and analytics: Does the CRM provide reporting and analytics on your marketing campaigns?

5. Customer Service and Support

A CRM should help you manage customer service requests and provide excellent customer support. Look for features like:

- Ticket management: Can you create and track customer support tickets?

- Knowledge base: Does the CRM provide a knowledge base where you can store helpful articles and FAQs?

- Live chat integration: Does the CRM integrate with live chat software?

- Customer satisfaction surveys: Can you send customer satisfaction surveys to gather feedback?

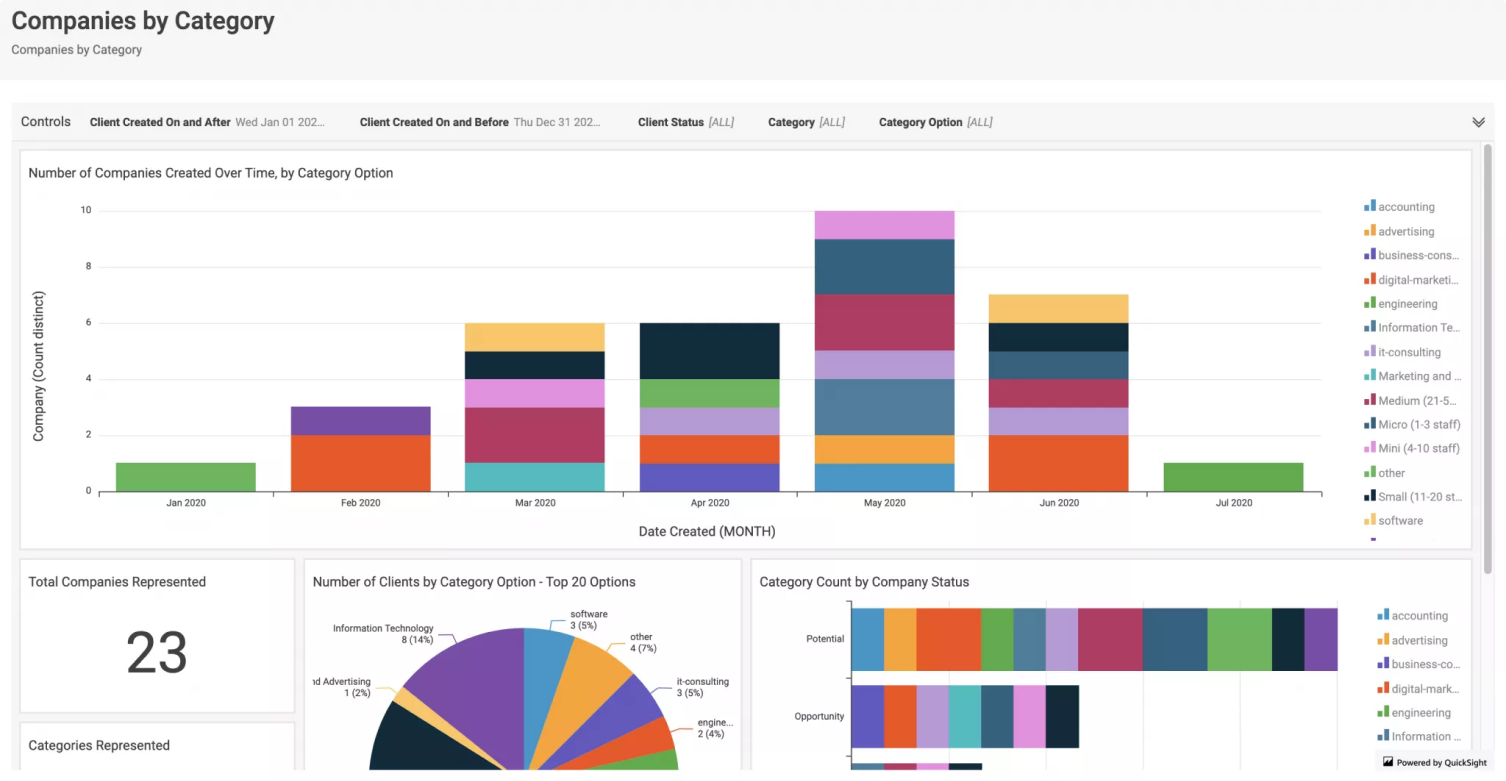

6. Reporting and Analytics

The demo should showcase the CRM’s reporting and analytics capabilities. Look for features like:

- Customizable dashboards: Can you create dashboards to track key metrics?

- Pre-built reports: Does the CRM provide pre-built reports on sales, marketing, and customer service performance?

- Data visualization: Does the CRM provide data visualization tools to help you understand your data?

- Data export: Can you export your data for further analysis?

7. Integrations

The demo should highlight the CRM’s integrations with other tools and platforms you use, such as email marketing software, accounting software, and social media platforms. This will ensure seamless data flow and streamline your workflow. Ask about integrations with the tools you currently use!

How to Evaluate a Small Business CRM Demo

Watching a CRM demo is just the first step. To make an informed decision, you need to evaluate the demo and the CRM platform itself. Here’s a step-by-step guide to help you:

1. Define Your Needs and Goals

Before you even watch a demo, take some time to define your specific needs and goals. What are your biggest pain points? What do you want to achieve with a CRM? Make a list of your must-have features and functionalities. This will help you focus on what’s important during the demo.

2. Prepare Your Questions

Don’t just sit back and passively watch the demo. Prepare a list of questions to ask the presenter. This will help you gather the information you need to make an informed decision. Here are some example questions:

- How easy is it to import my existing data?

- How customizable is the platform?

- Does the CRM integrate with the tools I currently use?

- What kind of training and support is available?

- What is the pricing structure?

- What is the user experience like? Is it intuitive?

- Can I easily generate the reports I need?

- Does the CRM offer mobile access?

3. Assess the User Interface

The user interface is crucial. Is it clean, intuitive, and easy to navigate? Does the platform feel user-friendly? A clunky or confusing interface can make it difficult for your team to adopt the CRM.

4. Evaluate the Features

Does the CRM offer the features you need? Does it meet your must-have requirements? Pay close attention to the features that are most important to your business. Does it have the flexibility to grow with your business?

5. Consider Scalability

Choose a CRM that can grow with your business. As your business expands, your needs will change. Make sure the CRM can accommodate your future needs.

6. Check for Integrations

Does the CRM integrate with the other tools and platforms you use? Integration is essential for seamless data flow and workflow efficiency. Ensure it integrates with your email marketing, accounting, and other key software.

7. Inquire About Support and Training

What kind of support and training is available? Does the vendor offer online resources, phone support, or on-site training? Make sure you’ll have the resources you need to get up and running and to troubleshoot any issues that arise.

8. Read Reviews and Case Studies

Before making a decision, read reviews and case studies from other small businesses. This will give you valuable insights into the CRM’s strengths and weaknesses and how it has helped other businesses achieve their goals.

9. Request a Free Trial or Pilot Program

Many CRM vendors offer free trials or pilot programs. Take advantage of these opportunities to test the platform yourself and see if it’s the right fit for your business. This hands-on experience is invaluable.

10. Compare Pricing and Plans

Compare the pricing and plans of different CRM platforms. Consider the features included in each plan and choose the one that offers the best value for your needs. Remember to factor in the long-term cost, including any add-ons or upgrades.

Top CRM Platforms for Small Businesses: A Quick Overview

While there are many CRM platforms available, some are particularly well-suited for small businesses. Here are a few of the top contenders, each with its own strengths:

1. HubSpot CRM

Best for: Businesses looking for a free, all-in-one CRM solution with strong marketing automation capabilities.

Key Features: Contact management, deal tracking, email marketing, marketing automation, reporting and analytics, free plan available.

Pros: Easy to use, free plan, strong marketing automation features, excellent integration with other HubSpot tools.

Cons: Limited features in the free plan, some advanced features require paid upgrades.

2. Zoho CRM

Best for: Businesses looking for a feature-rich, affordable CRM with extensive customization options.

Key Features: Contact management, lead management, sales pipeline management, marketing automation, customer service, customization options, mobile app.

Pros: Affordable, feature-rich, highly customizable, strong integration with other Zoho apps.

Cons: Can be overwhelming for beginners due to the extensive features, some advanced features require paid upgrades.

3. Pipedrive

Best for: Sales-focused businesses looking for a simple, intuitive CRM with a strong focus on pipeline management.

Key Features: Visual sales pipeline, deal tracking, contact management, activity tracking, reporting and analytics, mobile app.

Pros: User-friendly interface, strong pipeline management features, easy to use, good for sales teams.

Cons: Limited marketing automation features, less customization options compared to other platforms.

4. Freshsales (formerly Freshworks CRM)

Best for: Businesses looking for a CRM with integrated sales and customer support features.

Key Features: Contact management, lead management, sales pipeline management, phone integration, email integration, customer support features, reporting and analytics.

Pros: Integrated sales and customer support, easy to use, good for businesses that prioritize customer service.

Cons: Some features are only available in higher-priced plans, can be overwhelming for businesses that don’t need customer support features.

5. Salesforce Essentials

Best for: Small businesses looking for a powerful, scalable CRM with a wide range of features and integrations.

Key Features: Contact management, lead management, sales pipeline management, marketing automation, customer service, reporting and analytics, extensive integrations.

Pros: Powerful features, extensive integrations, highly scalable, well-established platform.

Cons: Can be expensive, complex to set up and manage, can be overwhelming for beginners.

Disclaimer: The “best” CRM for your business depends on your individual needs. Research and demo multiple platforms before making a decision. This is not an exhaustive list. There are many other excellent CRM solutions available.

Tips for Getting the Most Out of Your CRM Demo

To make the most of your CRM demo, remember these key tips:

- Be Prepared: Come prepared with a list of questions and a clear understanding of your needs.

- Be Engaged: Don’t be afraid to ask questions and participate in the demo.

- Focus on Your Needs: Focus on the features and functionalities that are most important to your business.

- Take Notes: Take detailed notes during the demo to help you remember key features and functionalities.

- Ask for a Trial: If possible, request a free trial or pilot program to test the platform yourself.

- Don’t Be Rushed: Take your time and don’t feel pressured to make a decision immediately.

- Consider Your Team: Think about how your team will use the CRM and how it will impact their workflow.

The Long-Term Benefits of a CRM for Small Businesses

Investing in a CRM is an investment in the future of your small business. The benefits extend far beyond just increased sales. Here’s a look at the long-term positive impacts:

- Improved Customer Loyalty: By providing personalized service and building stronger relationships, a CRM fosters customer loyalty. Loyal customers are more likely to make repeat purchases, refer your business to others, and provide valuable feedback.

- Increased Efficiency: Automating tasks and streamlining workflows frees up your team to focus on more strategic initiatives, such as product development, marketing, and sales.

- Better Decision-Making: Data-driven insights from your CRM empower you to make informed decisions about your business. You can identify trends, understand customer behavior, and optimize your strategies for maximum impact.

- Scalability: A well-chosen CRM can scale with your business, allowing you to manage your growing customer base and sales pipeline effectively. This prevents bottlenecks and ensures that your business can continue to grow.

- Competitive Advantage: By leveraging the power of a CRM, you can gain a competitive advantage over businesses that are still relying on manual processes and outdated systems.

The long-term benefits of a CRM far outweigh the initial investment. It’s a tool that helps you build a sustainable, customer-centric business.

Conclusion: Making the Right Choice for Your Small Business

Choosing the right CRM for your small business is a critical decision. By understanding the benefits of a CRM, knowing what to expect in a demo, and following the evaluation steps outlined in this article, you can make an informed choice that will drive growth, improve customer relationships, and streamline your operations.

Remember to:

- Define your needs and goals.

- Prepare your questions.

- Evaluate the user interface.

- Assess the features.

- Consider scalability.

- Check for integrations.

- Inquire about support and training.

- Read reviews and case studies.

- Request a free trial.

- Compare pricing and plans.

By taking the time to do your research and carefully evaluate your options, you can find the perfect CRM to empower your small business. Don’t be afraid to explore different options, watch multiple demos, and ask lots of questions. The right CRM can be a game-changer for your business, helping you achieve your goals and reach new heights of success. Start your journey today and unlock the full potential of your business!