Small Business CRM Demo: See How to Boost Sales, Delight Customers, and Scale Your Business

Introduction: Why a CRM Demo Matters for Your Small Business

Running a small business is a whirlwind. You’re juggling everything from sales and marketing to customer service and operations. Amidst the chaos, it’s easy for important details to slip through the cracks. This is where a Customer Relationship Management (CRM) system comes in. A CRM is more than just a contact list; it’s a central hub for all your customer interactions, designed to help you build stronger relationships, streamline your processes, and ultimately, grow your business. And the best way to understand its power? A small business CRM demo.

This comprehensive guide will walk you through everything you need to know about small business CRM demos. We’ll explore what to look for, what questions to ask, and how to choose the right CRM for your specific needs. We’ll also delve into the benefits of CRM, common features, and how to make the most of your demo experience. So, buckle up, because we’re about to embark on a journey that could transform the way you do business.

What is a CRM and Why Does Your Small Business Need One?

Before we dive into demos, let’s clarify what a CRM actually *is*. At its core, a CRM is a software solution designed to manage your interactions with current and potential customers. Think of it as a digital Rolodex on steroids, but it’s so much more than that. A good CRM provides a 360-degree view of your customer, consolidating data from various sources like website interactions, email exchanges, phone calls, and social media.

Here’s why a CRM is crucial for your small business:

- Improved Customer Relationships: By understanding your customers’ needs and preferences, you can tailor your communication and provide more personalized experiences.

- Increased Sales: CRM helps you track leads, manage your sales pipeline, and close deals more efficiently.

- Enhanced Efficiency: Automate repetitive tasks, freeing up your team to focus on more strategic initiatives.

- Better Data Insights: Gain valuable insights into your customer behavior and sales performance, allowing you to make data-driven decisions.

- Scalability: As your business grows, a CRM can scale with you, accommodating an increasing number of customers and transactions.

Without a CRM, you risk losing track of valuable customer information, missing out on sales opportunities, and struggling to keep up with the competition. It’s like trying to navigate a complex maze without a map – you might eventually find your way, but it’ll take much longer and you’ll likely encounter unnecessary obstacles.

Key Features to Look for in a Small Business CRM

Not all CRMs are created equal. The features you need will depend on the specific requirements of your business. However, there are some core features that are essential for any small business CRM. When you’re watching a CRM demo, pay close attention to these areas:

Contact Management

This is the foundation of any CRM. The system should allow you to easily store, organize, and access customer contact information, including names, addresses, phone numbers, email addresses, and social media profiles. Look for features like:

- Customizable fields: The ability to add custom fields to capture specific information relevant to your business.

- Segmentation: The ability to segment your contacts based on various criteria (e.g., demographics, purchase history, lead source).

- Import/Export: The ability to easily import and export contact data from other sources.

- Duplicate detection: A system that automatically identifies and merges duplicate contact records.

Sales Automation

Sales automation features streamline your sales process, saving you time and effort. Key features to consider include:

- Lead management: The ability to track leads, qualify them, and assign them to sales reps.

- Sales pipeline management: A visual representation of your sales pipeline, allowing you to track deals through each stage.

- Workflow automation: The ability to automate repetitive tasks, such as sending follow-up emails or updating deal stages.

- Deal tracking: The ability to track the progress of individual deals, including the value, probability of closing, and next steps.

Marketing Automation

Marketing automation features help you nurture leads, engage with customers, and improve your marketing ROI. Look for features like:

- Email marketing: The ability to create and send email campaigns, track open rates, and measure click-through rates.

- Lead nurturing: The ability to automate email sequences and personalized content based on lead behavior.

- Social media integration: The ability to connect with your social media accounts and track social media interactions.

- Landing page creation: The ability to create landing pages to capture leads and promote your products or services.

Customer Service and Support

A CRM should also provide tools to help you manage customer service inquiries and provide excellent support. Key features to consider include:

- Ticket management: The ability to track and manage customer support tickets.

- Knowledge base: A self-service knowledge base where customers can find answers to common questions.

- Live chat: The ability to provide real-time support through live chat.

- Customer feedback: The ability to collect and analyze customer feedback to improve your products and services.

Reporting and Analytics

Reporting and analytics features provide valuable insights into your sales performance, marketing effectiveness, and customer behavior. Look for features like:

- Customizable dashboards: The ability to create dashboards that display key performance indicators (KPIs) relevant to your business.

- Sales reports: Reports on sales performance, such as revenue, deals closed, and sales cycle length.

- Marketing reports: Reports on marketing campaign performance, such as open rates, click-through rates, and conversion rates.

- Customer reports: Reports on customer behavior, such as purchase history, customer lifetime value, and churn rate.

Integration with Other Tools

Your CRM should integrate seamlessly with other tools you use, such as:

- Email providers: Gmail, Outlook, etc.

- Accounting software: QuickBooks, Xero, etc.

- E-commerce platforms: Shopify, WooCommerce, etc.

- Project management tools: Asana, Trello, etc.

How to Prepare for a Small Business CRM Demo

Before you jump into a CRM demo, it’s crucial to do your homework. This will help you make the most of the demo and determine if the CRM is the right fit for your business. Here’s how to prepare:

1. Define Your Needs and Goals

What are you hoping to achieve with a CRM? What are your biggest pain points? What are the specific features you need? Take some time to identify your key requirements. This could include things like improving customer communication, streamlining your sales process, or gaining better insights into your customer data. Write down your goals and prioritize them. This will help you focus your attention during the demo and evaluate whether the CRM can meet your needs.

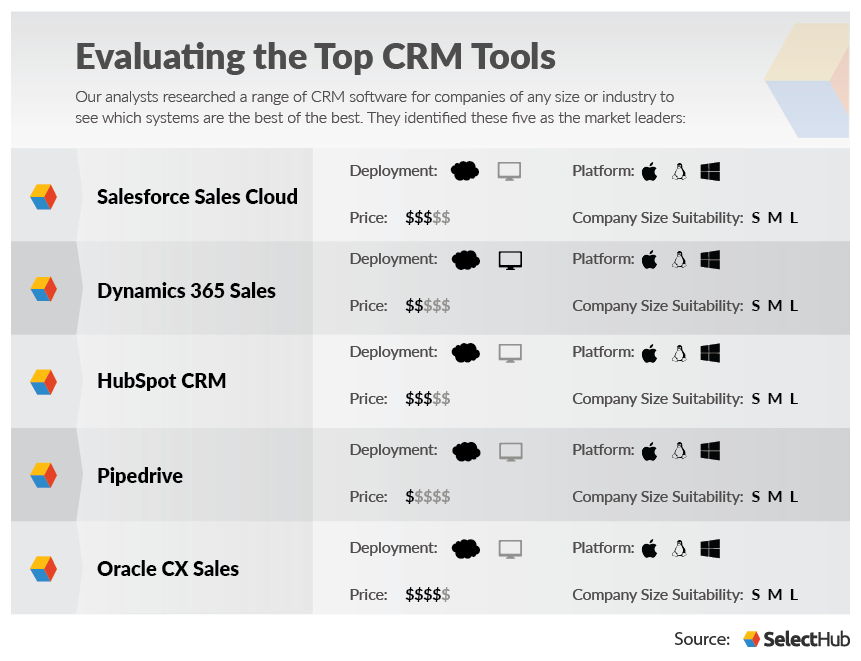

2. Research Potential CRM Providers

There are countless CRM providers out there, each with its own strengths and weaknesses. Researching your options beforehand will save you time and effort. Read reviews, compare features, and explore pricing plans. Some popular CRMs for small businesses include:

- HubSpot CRM: A free, all-in-one CRM with powerful features for sales, marketing, and customer service.

- Zoho CRM: A feature-rich CRM with a wide range of integrations and customization options.

- Salesforce Sales Cloud: A comprehensive CRM with advanced features and scalability.

- Pipedrive: A sales-focused CRM designed to help you manage your sales pipeline and close deals.

- Freshsales: A user-friendly CRM with a focus on ease of use and affordability.

Create a shortlist of potential CRM providers based on your research.

3. Prepare a List of Questions

Don’t be shy about asking questions during the demo. This is your opportunity to learn more about the CRM and how it can benefit your business. Prepare a list of questions in advance, focusing on the features that are most important to you. Here are some examples:

- How easy is it to import my existing data?

- Does the CRM integrate with the tools I already use?

- What kind of training and support is available?

- What are the pricing plans and what do they include?

- How scalable is the CRM? Can it grow with my business?

- What security measures are in place to protect my data?

- What are the reporting and analytics capabilities?

- Can I customize the CRM to meet my specific needs?

4. Have a Clear Understanding of Your Current Processes

Before you see a demo, take the time to map out your current processes. How do you currently manage leads? How do you track sales? How do you handle customer service inquiries? Understanding your existing workflows will help you assess how the CRM can improve them. You’ll also be able to ask more specific questions about how the CRM can be used to streamline your operations.

5. Identify Key Stakeholders

Who in your organization will be using the CRM? Make sure to involve them in the demo process. Get their input on their needs and expectations. This will help you choose a CRM that meets the needs of your entire team. If possible, include a representative from each department (e.g., sales, marketing, customer service) in the demo.

What to Expect During a CRM Demo

A CRM demo is your chance to see the CRM in action. The presenter will walk you through the key features, show you how they work, and answer your questions. Here’s what you can expect:

1. Introduction and Overview

The presenter will start with an introduction to the CRM and its key features. They’ll likely provide a brief overview of the company and its mission. They’ll also ask about your business and your specific needs.

2. Feature Demonstrations

The presenter will then demonstrate the key features of the CRM. They’ll show you how to use the system to manage contacts, track leads, automate sales processes, and generate reports. Pay close attention to the features that are most important to you. Take notes and ask questions.

3. Q&A Session

The presenter will answer your questions about the CRM. This is your opportunity to clarify any doubts and get more information. Don’t hesitate to ask specific questions about the features, integrations, pricing, and support.

4. Customization and Integration Discussion

The presenter may discuss how the CRM can be customized to meet your specific needs and how it integrates with other tools you use. This is an important part of the demo, as it will help you understand how the CRM can fit into your existing workflow.

5. Pricing and Implementation Discussion

The presenter will likely discuss the pricing plans and implementation process. They may also provide information on training and support. Make sure to understand the costs involved and the level of support you’ll receive.

Questions to Ask During a Small Business CRM Demo

To get the most out of your CRM demo, come prepared with a list of questions. Here are some key areas to focus on:

Functionality

- How easy is it to navigate the interface?

- How customizable is the system? Can I add custom fields and workflows?

- How intuitive is the user experience?

- Does the CRM offer mobile access?

- Does the CRM support multiple currencies and languages?

Sales and Marketing

- How does the CRM help me manage leads and opportunities?

- Does the CRM offer sales pipeline management features?

- Can I automate email marketing campaigns?

- Does the CRM integrate with social media platforms?

- How does the CRM help me track sales performance?

Customer Service

- Does the CRM offer ticket management features?

- Does the CRM integrate with live chat?

- Can I create a knowledge base for self-service support?

- How does the CRM help me track customer satisfaction?

Integration

- Does the CRM integrate with my existing tools (e.g., email, accounting, e-commerce)?

- How easy is it to integrate the CRM with other systems?

- Does the CRM offer an API for custom integrations?

Reporting and Analytics

- What types of reports are available?

- Can I create custom reports?

- How often is the data updated?

- Does the CRM offer real-time dashboards?

Pricing and Support

- What are the pricing plans and what do they include?

- What kind of training and support is available?

- Is there a free trial or demo account?

- What is the onboarding process like?

- What are the terms of service and data security policies?

Making the Most of Your CRM Demo: Practical Tips

Here are some practical tips to help you make the most of your CRM demo:

- Come Prepared: Have your list of questions ready. Knowing your needs and priorities will help you focus on the most important aspects of the demo.

- Take Notes: Write down key features, pros and cons, and any unanswered questions.

- Ask Specific Questions: Don’t be afraid to ask detailed questions about the features and functionality. The more information you gather, the better equipped you’ll be to make an informed decision.

- Focus on Your Needs: Evaluate the CRM based on how well it meets your specific business requirements.

- Don’t Be Afraid to Ask for a Second Demo: If you need more information or want to see a specific feature in action, don’t hesitate to ask for a follow-up demo.

- Get a Free Trial: If possible, sign up for a free trial to test the CRM yourself before making a decision.

- Consider the User Experience: Pay attention to the user interface and ease of use. A CRM that is difficult to use will be less effective.

- Consider the Long-Term: Choose a CRM that can scale with your business as it grows.

After the Demo: Evaluating Your Options and Making a Decision

Once you’ve completed your CRM demos, it’s time to evaluate your options and make a decision. Here’s how to do it:

1. Review Your Notes

Go back and review the notes you took during each demo. Compare the features, pricing, and support options of each CRM. Make a list of the pros and cons of each option.

2. Score Each CRM

Create a scoring system to help you evaluate each CRM. Assign points to each feature based on its importance to your business. For example, you might give more points to features that are critical to your sales process.

3. Consider the User Experience

If you had the chance to test the CRM during a free trial or demo, consider the user experience. Is the interface intuitive and easy to navigate? Is the system easy to learn and use? A user-friendly CRM will save you time and effort in the long run.

4. Evaluate the Pricing and Support

Compare the pricing plans of each CRM. Consider the features included in each plan and the level of support offered. Make sure you understand the costs involved and the terms of service.

5. Get Feedback from Your Team

If you involved other members of your team in the demo process, get their feedback. What did they like or dislike about each CRM? Their input can help you make a more informed decision.

6. Make a Decision

Based on your evaluation, choose the CRM that best meets your needs and budget. Consider the long-term benefits of each option and choose the one that you believe will help you grow your business.

7. Plan for Implementation

Once you’ve chosen a CRM, develop a plan for implementation. This should include data migration, user training, and ongoing support. Implement the CRM in stages to minimize disruption and ensure a smooth transition.

Conclusion: Investing in a CRM for Long-Term Success

Choosing the right CRM for your small business is a significant investment, but it’s an investment that can pay off handsomely. By streamlining your sales process, improving customer relationships, and gaining valuable data insights, a CRM can help you grow your business and achieve long-term success. A small business CRM demo is the perfect way to evaluate your options and find the perfect solution for your needs. By following the steps outlined in this guide, you can make an informed decision and choose a CRM that will empower your team and drive your business forward. So, take the time to research, prepare, and ask the right questions. Your future success depends on it.