The Power of CRM for Small Businesses: A Lead Generation Game Changer

In the fast-paced world of business, especially for small businesses, staying ahead requires more than just a great product or service. It demands a keen understanding of your customers and the ability to effectively manage leads. This is where Customer Relationship Management (CRM) systems come into play, transforming the way small businesses operate and interact with potential clients. CRM isn’t just a software; it’s a strategic approach to building stronger customer relationships and driving sustainable growth. For small businesses, the right CRM can be the difference between struggling to stay afloat and flourishing in a competitive market.

This article delves into the world of CRM, specifically focusing on how it can revolutionize lead management for small businesses. We’ll explore the core functionalities of CRM, its benefits, how to choose the right system, and how to effectively implement it to maximize your lead generation efforts. Get ready to discover how a CRM system can become your most valuable asset in converting leads into loyal customers.

Understanding CRM: Beyond the Basics

At its heart, a CRM system is a technology that helps businesses manage their interactions with current and potential customers. It’s a centralized hub where all customer-related information is stored, organized, and accessible. This includes contact details, communication history, purchase records, and any other relevant data. But CRM is much more than just a digital address book; it’s a powerful tool for understanding customer behavior, personalizing interactions, and streamlining sales and marketing processes.

Here are some key components of a CRM system:

- Contact Management: Centralized storage of customer contact information, including names, addresses, phone numbers, email addresses, and social media profiles.

- Lead Management: Tracking leads through the sales pipeline, from initial contact to conversion.

- Sales Automation: Automating repetitive sales tasks, such as email follow-ups and appointment scheduling.

- Marketing Automation: Sending targeted marketing campaigns and personalized communications based on customer behavior.

- Reporting and Analytics: Providing insights into sales performance, customer behavior, and marketing campaign effectiveness.

- Integration: Integrating with other business tools, such as email, accounting software, and social media platforms.

For small businesses, these features can be invaluable. They provide a 360-degree view of each customer, enabling businesses to understand their needs, preferences, and pain points. This understanding allows for more personalized and effective communication, which ultimately leads to higher conversion rates and increased customer loyalty.

The Benefits of CRM for Small Business Lead Generation

Implementing a CRM system can bring a multitude of benefits to small businesses, particularly in the realm of lead generation. Here are some of the key advantages:

Improved Lead Capture and Qualification

A CRM system helps you capture leads from various sources, such as website forms, social media, and email campaigns. It then allows you to qualify these leads by tracking their interactions with your business and assessing their potential to become customers. This process helps you prioritize your efforts and focus on the most promising leads, saving you time and resources.

Enhanced Lead Nurturing

CRM systems enable you to nurture leads through the sales funnel by providing personalized communication and targeted content. You can send automated email sequences, schedule follow-up calls, and track lead engagement to ensure that they stay engaged with your business. This nurturing process increases the likelihood of converting leads into customers.

Increased Sales Productivity

By automating repetitive tasks and providing easy access to customer information, CRM systems free up your sales team to focus on more strategic activities, such as building relationships and closing deals. This increased productivity can lead to higher sales volumes and revenue growth.

Better Customer Segmentation

CRM systems allow you to segment your customers based on various criteria, such as demographics, purchase history, and engagement level. This segmentation enables you to tailor your marketing messages and sales efforts to specific customer groups, increasing the relevance and effectiveness of your communications.

Improved Customer Retention

By providing a centralized view of customer interactions and preferences, CRM systems help you build stronger customer relationships. You can use this information to personalize your communications, provide excellent customer service, and proactively address customer needs. This leads to higher customer satisfaction and retention rates.

Data-Driven Decision Making

CRM systems provide valuable data and insights into your sales and marketing performance. You can track key metrics, such as lead conversion rates, sales cycle length, and customer lifetime value. This data allows you to make informed decisions about your sales and marketing strategies, optimizing your efforts for maximum impact.

Choosing the Right CRM System for Your Small Business

Selecting the right CRM system is crucial for its successful implementation and effectiveness. There are many CRM options available, each with its own features, pricing, and target audience. Here’s a guide to help you choose the best CRM for your small business:

Assess Your Needs

Before you start evaluating CRM systems, take the time to assess your specific needs and requirements. Consider the following questions:

- What are your primary goals for implementing a CRM system? (e.g., improve lead generation, increase sales, enhance customer service)

- What features are essential for your business? (e.g., contact management, lead tracking, sales automation, marketing automation)

- How many users will be using the CRM system?

- What is your budget for the CRM system?

- Do you need to integrate the CRM system with other business tools? (e.g., email, accounting software, website)

Answering these questions will help you narrow down your options and identify the CRM systems that are best suited for your business.

Research Different CRM Systems

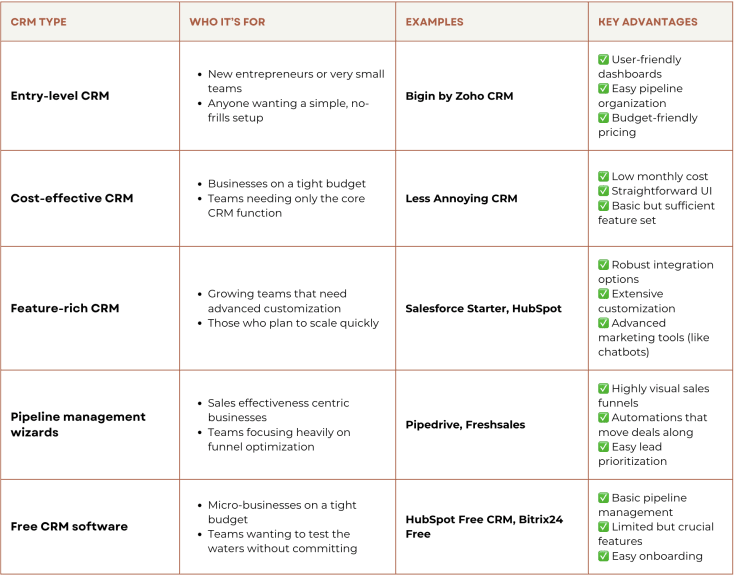

Once you have a clear understanding of your needs, it’s time to research different CRM systems. Here are some popular options for small businesses:

- HubSpot CRM: A free CRM system with a wide range of features, including contact management, lead tracking, and sales automation.

- Zoho CRM: A comprehensive CRM system with a variety of features, including sales automation, marketing automation, and customer service tools.

- Salesforce Sales Cloud: A powerful CRM system with a wide range of features and integrations, suitable for businesses of all sizes.

- Pipedrive: A sales-focused CRM system designed for small businesses, with a user-friendly interface and intuitive features.

- Freshsales: A CRM system with a focus on sales and marketing automation, offering features like built-in phone and email.

Read reviews, compare features, and explore pricing plans to find the CRM systems that align with your needs and budget.

Consider Scalability and Integrations

When choosing a CRM system, consider its scalability and integration capabilities. Make sure the system can grow with your business and integrate with other tools you use, such as email marketing platforms, accounting software, and social media channels. This integration will streamline your workflows and improve data consistency.

Evaluate Pricing and Support

CRM systems come with various pricing models, including free, freemium, and paid subscriptions. Evaluate the pricing plans of different CRM systems and choose the one that fits your budget and provides the features you need. Also, consider the level of customer support offered by the CRM provider. Look for systems that offer helpful documentation, tutorials, and responsive customer support channels.

Test the System

Before committing to a CRM system, take advantage of free trials or demos to test the system and see if it meets your needs. This will give you a hands-on experience with the system and allow you to assess its user-friendliness and functionality.

Implementing Your CRM System: A Step-by-Step Guide

Once you’ve chosen a CRM system, the next step is to implement it. Here’s a step-by-step guide to help you get started:

Plan Your Implementation

Before you start implementing your CRM system, create a detailed implementation plan. This plan should include the following:

- Define your goals and objectives: What do you want to achieve with the CRM system?

- Identify key stakeholders: Who will be involved in the implementation process?

- Create a timeline: Set realistic deadlines for each stage of the implementation.

- Allocate resources: Determine the budget and resources needed for the implementation.

A well-defined plan will help you stay organized and on track throughout the implementation process.

Import Your Data

Import your existing customer data into the CRM system. This may include contact information, purchase history, and communication records. Ensure that your data is accurate and up-to-date before importing it into the system. Many CRM systems offer data import tools to simplify this process.

Customize the System

Customize the CRM system to fit your specific business needs. This may involve setting up custom fields, creating sales pipelines, and configuring workflows. Take the time to configure the system to your liking to maximize its effectiveness.

Train Your Team

Provide training to your team on how to use the CRM system. This training should cover all the features and functionalities of the system and how they can be used to improve their work. Offer ongoing training and support to ensure that your team is using the system effectively.

Integrate with Other Tools

Integrate the CRM system with other business tools, such as email marketing platforms, accounting software, and website forms. This integration will streamline your workflows and improve data consistency. Make sure that all integrations are properly configured and tested.

Monitor and Optimize

Once the CRM system is implemented, monitor its performance and make adjustments as needed. Track key metrics, such as lead conversion rates, sales cycle length, and customer satisfaction. Use this data to optimize your sales and marketing strategies and ensure that you are getting the most out of your CRM system.

Maximizing Lead Generation with Your CRM

Now that you have a CRM system in place, it’s time to leverage it to maximize your lead generation efforts. Here are some strategies to help you:

Capture Leads from Multiple Sources

Integrate your CRM system with various lead capture sources, such as your website, social media, and email marketing campaigns. Use lead capture forms, landing pages, and social media ads to collect lead information. This will ensure that you capture all potential leads and track their interactions with your business.

Segment Your Leads

Segment your leads based on various criteria, such as demographics, behavior, and lead source. This segmentation will allow you to tailor your marketing messages and sales efforts to specific lead groups, increasing the relevance and effectiveness of your communications.

Automate Lead Nurturing

Use automated email sequences and workflows to nurture leads through the sales funnel. Send targeted content, such as blog posts, webinars, and case studies, to keep leads engaged and informed. Automate follow-up calls and tasks to ensure that you stay in touch with leads and move them closer to conversion.

Personalize Your Communications

Use the data stored in your CRM system to personalize your communications with leads. Address them by name, reference their past interactions with your business, and tailor your messages to their specific needs and interests. Personalized communications are more likely to resonate with leads and increase conversion rates.

Track and Analyze Your Results

Track key metrics, such as lead conversion rates, sales cycle length, and customer lifetime value. Analyze this data to identify what’s working and what’s not. Use this information to optimize your lead generation strategies and improve your results. Regularly review your CRM data to gain insights into your lead generation process.

Provide Excellent Customer Service

Use your CRM system to provide excellent customer service to your leads. Respond to their inquiries promptly, provide helpful information, and address their concerns. Excellent customer service builds trust and increases the likelihood of converting leads into customers.

Common Pitfalls to Avoid

While CRM systems offer numerous benefits, there are also common pitfalls to avoid to ensure their successful implementation and use. Here are some of them:

Choosing the Wrong System

Selecting a CRM system that doesn’t fit your business needs can lead to wasted time, resources, and frustration. Thoroughly assess your needs and research different CRM options to find the system that’s the best fit for your business.

Poor Data Quality

Inaccurate, incomplete, or outdated data can undermine the effectiveness of your CRM system. Ensure that your data is accurate, up-to-date, and consistently maintained. Implement data validation rules and regularly review your data to maintain its quality.

Lack of User Adoption

If your team doesn’t embrace the CRM system, it won’t be effective. Provide adequate training, support, and encouragement to ensure that your team uses the system consistently. Highlight the benefits of using the system and address any concerns or resistance.

Ignoring Integration

Failing to integrate your CRM system with other business tools can limit its effectiveness. Integrate the CRM system with your email marketing platform, website, accounting software, and other relevant tools to streamline your workflows and improve data consistency.

Not Measuring Results

Without tracking and analyzing your CRM data, you won’t know if your efforts are paying off. Track key metrics, such as lead conversion rates, sales cycle length, and customer satisfaction. Use this data to optimize your sales and marketing strategies and improve your results.

The Future of CRM in Small Business Lead Generation

The landscape of CRM is constantly evolving, with new technologies and trends emerging. Here are some trends that are shaping the future of CRM for small business lead generation:

Artificial Intelligence (AI) and Machine Learning

AI and machine learning are transforming CRM by automating tasks, providing insights, and personalizing customer experiences. AI-powered CRM systems can analyze large datasets to identify patterns, predict customer behavior, and recommend actions. This can lead to more efficient lead generation, improved sales performance, and enhanced customer relationships.

Mobile CRM

Mobile CRM systems allow sales and marketing teams to access customer data and manage leads on the go. This enables them to stay connected with customers, respond to inquiries quickly, and close deals from anywhere. Mobile CRM is particularly beneficial for small businesses with a mobile workforce.

Social CRM

Social CRM integrates social media channels with CRM systems. This allows businesses to monitor social media conversations, engage with customers, and track social media leads. Social CRM helps businesses build brand awareness, generate leads, and provide better customer service.

Personalization

Personalization is becoming increasingly important in CRM. Customers expect personalized experiences, and businesses that can deliver them are more likely to win their loyalty. CRM systems are enabling businesses to personalize their communications, offers, and interactions based on customer data and preferences.

Focus on Customer Experience

The focus of CRM is shifting from simply managing customer data to providing exceptional customer experiences. Businesses are using CRM systems to understand customer needs, personalize interactions, and build long-lasting relationships. This customer-centric approach is essential for driving sustainable growth.

Conclusion: Embrace CRM for Lead Generation Success

In conclusion, a CRM system is a powerful tool that can transform the way small businesses generate and manage leads. By implementing the right CRM system and following the strategies outlined in this article, you can improve your lead capture and qualification, enhance lead nurturing, increase sales productivity, and drive sustainable growth.

Don’t let your leads fall through the cracks. Embrace the power of CRM and unlock your business’s full potential. With the right CRM system and a well-defined strategy, you can turn leads into loyal customers and build a thriving business. Take the first step today and start exploring the world of CRM!