Scaling Up: How CRM Software Empowers Small Businesses to Grow

Introduction: The Small Business Dream and the CRM Reality

Every small business owner starts with a dream: to build something great, to connect with customers, and to see their venture flourish. But the path to success is rarely smooth. It’s often paved with challenges, from managing customer relationships to juggling day-to-day operations. This is where Customer Relationship Management (CRM) software steps in, promising to be the secret weapon that can help small businesses not just survive, but thrive. But the question is, can CRM truly deliver on this promise, especially when it comes to scalability? This article dives deep into the world of CRM for small businesses, exploring how it can be a game-changer and, importantly, how it can grow alongside your business.

What is CRM and Why Does It Matter for Small Businesses?

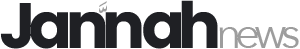

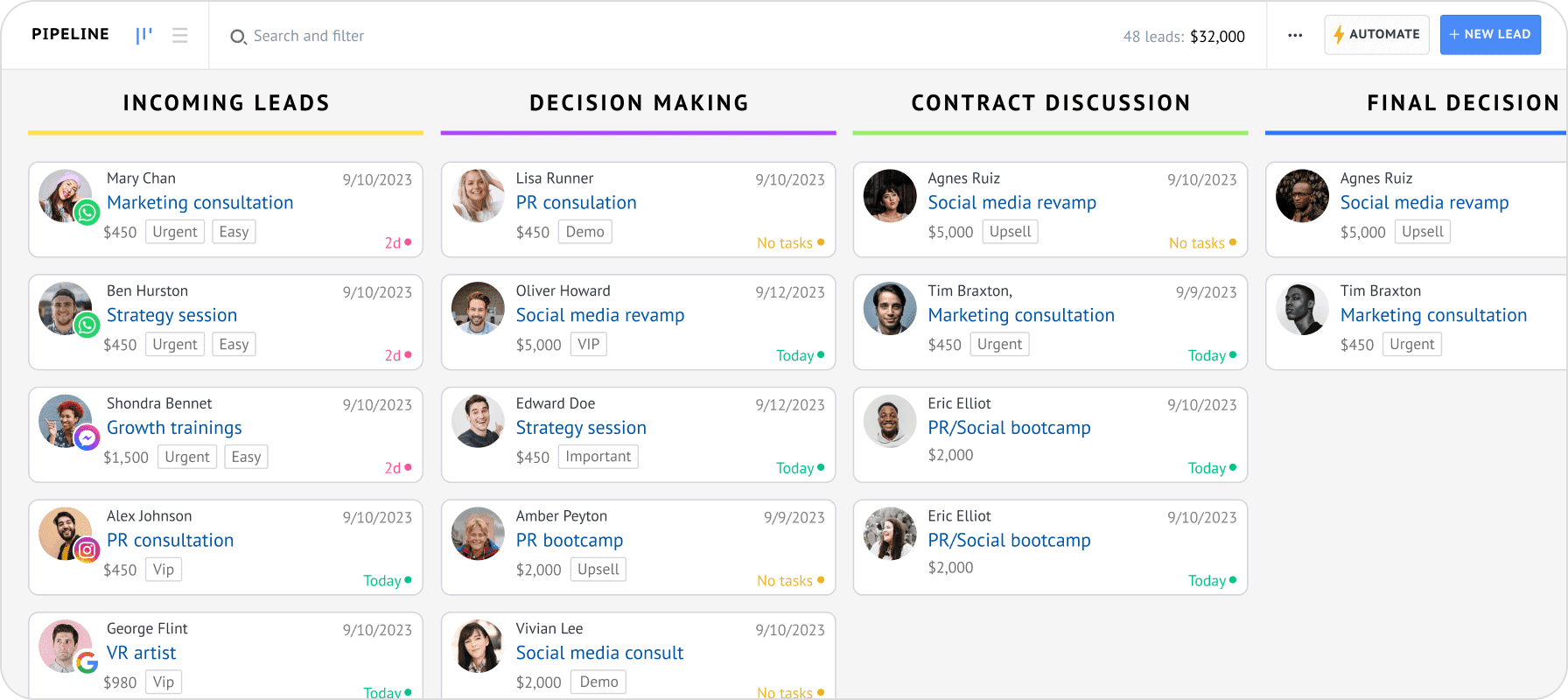

At its core, CRM is a system for managing all your interactions with current and potential customers. It’s a central hub where you store contact information, track sales leads, monitor customer service interactions, and analyze data to understand customer behavior. For a small business, this means:

- Improved Customer Relationships: CRM helps you remember the details. You can personalize interactions, anticipate needs, and build stronger relationships.

- Increased Sales: By tracking leads and sales opportunities, CRM helps you close deals faster and more efficiently.

- Enhanced Efficiency: Automate repetitive tasks, freeing up your team to focus on more strategic initiatives.

- Data-Driven Decisions: CRM provides valuable insights into customer behavior, allowing you to make informed decisions about your marketing, sales, and customer service strategies.

In a world where customer experience is king, CRM is no longer a luxury; it’s a necessity. It’s the foundation upon which you can build a loyal customer base and drive sustainable growth. But the key is to choose a CRM that can scale with your business. You don’t want to outgrow your system in a year or two.

The Scalability Challenge: Why It’s Crucial for Small Business Success

Scalability is the ability of a system to handle a growing workload. In the context of CRM, it means the software can accommodate more users, more data, and more complex processes as your business expands. This is a critical consideration for small businesses because:

- Avoiding Growing Pains: A CRM that can’t scale will quickly become a bottleneck, hindering your ability to manage a larger customer base and handle increased sales volume.

- Cost-Effectiveness: Choosing a scalable CRM from the outset can save you money in the long run. You won’t need to migrate to a new system every few years.

- Future-Proofing Your Investment: A scalable CRM ensures that your investment in the software will continue to provide value as your business evolves.

- Maintaining a Consistent Customer Experience: As you grow, you need to maintain the same level of personalized service that your customers have come to expect. A scalable CRM helps you do that.

Imagine trying to squeeze a growing plant into a tiny pot. Eventually, the plant will be stunted. The same applies to your business and your CRM. A non-scalable CRM will restrict your growth potential.

Key Features to Look for in a Scalable CRM for Small Businesses

Not all CRM systems are created equal. When choosing a CRM for your small business, pay close attention to these features that are essential for scalability:

1. Cloud-Based Architecture

Cloud-based CRM solutions offer a significant advantage when it comes to scalability. They run on remote servers, meaning you don’t need to invest in expensive hardware or worry about IT infrastructure. Cloud CRM providers handle the upgrades, maintenance, and data backups, allowing you to focus on your business. As your business grows, you can easily increase your storage capacity, add more users, and access more features without any major disruptions.

2. Customization and Integration Capabilities

Your business is unique, and your CRM should reflect that. Look for a CRM that allows you to customize fields, workflows, and reports to fit your specific needs. Integration capabilities are also crucial. The ability to integrate with other business tools, such as email marketing platforms, accounting software, and e-commerce platforms, is essential for streamlining your operations and ensuring data consistency. As your business grows, you’ll likely add new tools to your tech stack, so the ability to integrate with those tools is paramount.

3. User Management and Role-Based Permissions

As your team expands, you’ll need to control access to sensitive data and ensure that each user has the appropriate level of permissions. A scalable CRM allows you to create user roles, assign permissions, and track user activity. This helps you maintain data security, improve collaboration, and ensure that your team members can access the information they need to do their jobs effectively.

4. Automation Features

Automation is a key driver of efficiency. Look for a CRM that offers a range of automation features, such as automated email campaigns, lead scoring, and task management. As your business grows, automation can help you streamline your processes, reduce manual tasks, and free up your team to focus on more strategic initiatives. This is particularly important for sales and marketing teams, who can automate repetitive tasks like follow-up emails and lead qualification.

5. Reporting and Analytics

Data is the lifeblood of any successful business. A scalable CRM provides robust reporting and analytics capabilities, allowing you to track key metrics, identify trends, and make data-driven decisions. As your business grows, you’ll need more sophisticated reporting and analytics to understand your customer behavior, measure the effectiveness of your marketing campaigns, and identify areas for improvement. Look for a CRM that offers customizable dashboards, detailed reports, and the ability to export data for further analysis.

6. Mobile Accessibility

In today’s fast-paced world, you need to be able to access your CRM data from anywhere, at any time. A mobile-friendly CRM allows your team members to stay connected, track leads, manage customer interactions, and access important information on the go. This is especially important for sales teams who spend a lot of time out in the field. Mobile accessibility ensures that your team can stay productive, even when they’re away from the office.

Choosing the Right CRM: A Step-by-Step Guide

Selecting the right CRM for your small business is a crucial decision. Here’s a step-by-step guide to help you make the right choice:

1. Define Your Needs and Goals

Before you start evaluating CRM systems, take the time to define your specific needs and goals. What are your pain points? What do you want to achieve with a CRM? What are your key performance indicators (KPIs)? Having a clear understanding of your requirements will help you narrow down your options and choose a CRM that’s a good fit for your business.

2. Research and Shortlist CRM Vendors

Once you know what you’re looking for, start researching different CRM vendors. Read reviews, compare features, and consider the pricing models. Create a shortlist of potential CRM systems that meet your criteria. Pay attention to the vendor’s reputation, customer support, and scalability options.

3. Evaluate and Compare CRM Systems

Once you have a shortlist, it’s time to evaluate and compare the different CRM systems. Consider factors such as ease of use, features, integrations, and pricing. Many CRM vendors offer free trials or demos, which allow you to test the system and see if it’s a good fit for your business. Don’t be afraid to ask questions and request a personalized demo to address your specific needs.

4. Consider the Cost of Ownership

CRM software involves more than just the initial software cost. Consider the total cost of ownership, including implementation, training, ongoing maintenance, and any additional modules or features you may need. Factor in the time and resources required for data migration and user training. Choose a CRM that fits your budget and provides a good return on investment.

5. Plan for Implementation and Training

Once you’ve chosen a CRM, plan for implementation and training. Develop a detailed implementation plan, including timelines, responsibilities, and milestones. Provide adequate training to your team to ensure that they know how to use the system effectively. Consider offering ongoing training and support to help your team stay up-to-date with the latest features and best practices.

Common CRM Mistakes and How to Avoid Them

Even with the best intentions, small businesses can make mistakes when implementing a CRM. Here are some common pitfalls and how to avoid them:

1. Not Defining Clear Goals

Without clear goals, you won’t be able to measure the success of your CRM implementation. Before you implement a CRM, define your objectives, KPIs, and success metrics. This will help you track your progress and make adjustments as needed.

2. Choosing the Wrong CRM

Not all CRM systems are created equal. Choosing the wrong CRM can lead to frustration, wasted time, and a failed implementation. Carefully evaluate your needs and choose a CRM that’s a good fit for your business. Consider the scalability of the system and whether it can grow with you.

3. Not Getting Buy-In from Your Team

If your team doesn’t embrace the CRM, it won’t be successful. Involve your team in the selection process, provide adequate training, and communicate the benefits of the CRM. Make sure your team understands how the CRM will help them do their jobs more effectively.

4. Not Migrating Data Properly

Data migration can be a complex process. If you don’t migrate your data properly, you could lose valuable information or end up with inaccurate data. Plan your data migration carefully, and consider using a data migration tool or seeking help from a CRM expert.

5. Not Providing Ongoing Training and Support

The CRM implementation is just the beginning. Provide ongoing training and support to your team to ensure that they’re using the system effectively. Stay up-to-date with the latest features and best practices. Encourage your team to ask questions and seek help when needed.

Examples of Scalable CRM Solutions for Small Businesses

Here are a few examples of CRM solutions that are known for their scalability and suitability for small businesses (Note: This is not an exhaustive list, and the best choice depends on your specific needs):

- HubSpot CRM: Offers a free CRM plan with a wide range of features, making it a great option for startups and small businesses. It’s also highly scalable and offers paid plans with more advanced features as your business grows.

- Zoho CRM: A popular choice for small businesses, Zoho CRM offers a comprehensive suite of features at an affordable price. It’s highly customizable and offers a range of integrations.

- Salesforce Sales Cloud: While more complex and expensive than other options, Salesforce offers a powerful and highly scalable CRM platform. It’s a good choice for businesses that anticipate rapid growth or have complex sales processes.

- Pipedrive: Specifically designed for sales teams, Pipedrive is known for its user-friendly interface and focus on deal management. It’s a good option for small businesses that want a CRM that’s easy to use and helps them close deals.

Remember to research these and other options to find the best fit for your specific business requirements.

Conclusion: Embracing CRM for Sustainable Growth

In the competitive landscape of today’s business world, CRM is no longer optional; it’s essential. For small businesses, the right CRM is a catalyst for growth, a tool that empowers you to build stronger customer relationships, streamline operations, and make data-driven decisions. Choosing a scalable CRM is paramount. It ensures that your system can grow alongside your business, avoiding the frustrations of outgrowing your software and ensuring that your investment provides long-term value. By carefully considering your needs, researching your options, and planning for implementation, you can harness the power of CRM to unlock your business’s full potential and achieve sustainable growth. Embrace the power of CRM, and watch your small business blossom into something truly extraordinary.