Supercharge Your Small Business: How CRM Fuels Growth and Success

In the dynamic world of small businesses, growth isn’t just a goal; it’s the lifeblood. Every entrepreneur understands the relentless pursuit of customers, the constant juggle of tasks, and the pivotal role of efficiency. But what if there was a single tool, a digital Swiss Army knife, that could streamline your operations, boost your sales, and foster lasting customer relationships? Enter the world of Customer Relationship Management (CRM) systems. This isn’t just about fancy software; it’s about fundamentally changing how you interact with your customers and, consequently, how your business thrives. This comprehensive guide delves into the power of CRM for small business growth, exploring its benefits, implementation strategies, and real-world examples to help you unlock your full potential.

Understanding the Essence of CRM

At its core, a CRM system is more than just a contact database. It’s a centralized platform that organizes all your customer interactions and data in one place. Imagine a single, unified view of every customer, from their initial inquiry to their ongoing support requests. This comprehensive perspective empowers you to understand their needs, preferences, and behaviors, enabling you to tailor your interactions and deliver exceptional experiences.

Think of it like this: before CRM, your customer information might be scattered across spreadsheets, email inboxes, and individual employee memories. This fragmented approach leads to lost opportunities, duplicated efforts, and a frustrating experience for both your team and your customers. CRM solves this by consolidating all that information, providing everyone in your organization with instant access to the most up-to-date customer data.

Key Components of a CRM System

- Contact Management: Centralized storage of customer information, including contact details, communication history, and purchase records.

- Sales Automation: Streamlining the sales process, from lead generation to deal closing, with automated workflows and reminders.

- Marketing Automation: Automating marketing campaigns, such as email blasts and social media posts, to nurture leads and drive engagement.

- Customer Service: Managing customer inquiries, support tickets, and feedback to ensure prompt and effective resolution.

- Analytics and Reporting: Tracking key performance indicators (KPIs), generating reports, and gaining insights into customer behavior and sales performance.

The Tangible Benefits of CRM for Small Businesses

The advantages of implementing a CRM system for your small business are numerous and far-reaching. It’s not just about keeping track of customers; it’s about transforming your entire business strategy and driving sustainable growth. Let’s break down the key benefits:

1. Enhanced Customer Relationships

At the heart of any successful business lies strong customer relationships. CRM empowers you to build and nurture these relationships by providing a 360-degree view of each customer. You can:

- Personalize Interactions: Tailor your communications and offers based on individual customer preferences and purchase history.

- Improve Communication: Track all interactions, ensuring consistent and timely communication across all channels.

- Provide Proactive Support: Anticipate customer needs and offer solutions before they even ask.

- Increase Customer Loyalty: Build stronger relationships, leading to increased customer retention and lifetime value.

2. Boosted Sales Performance

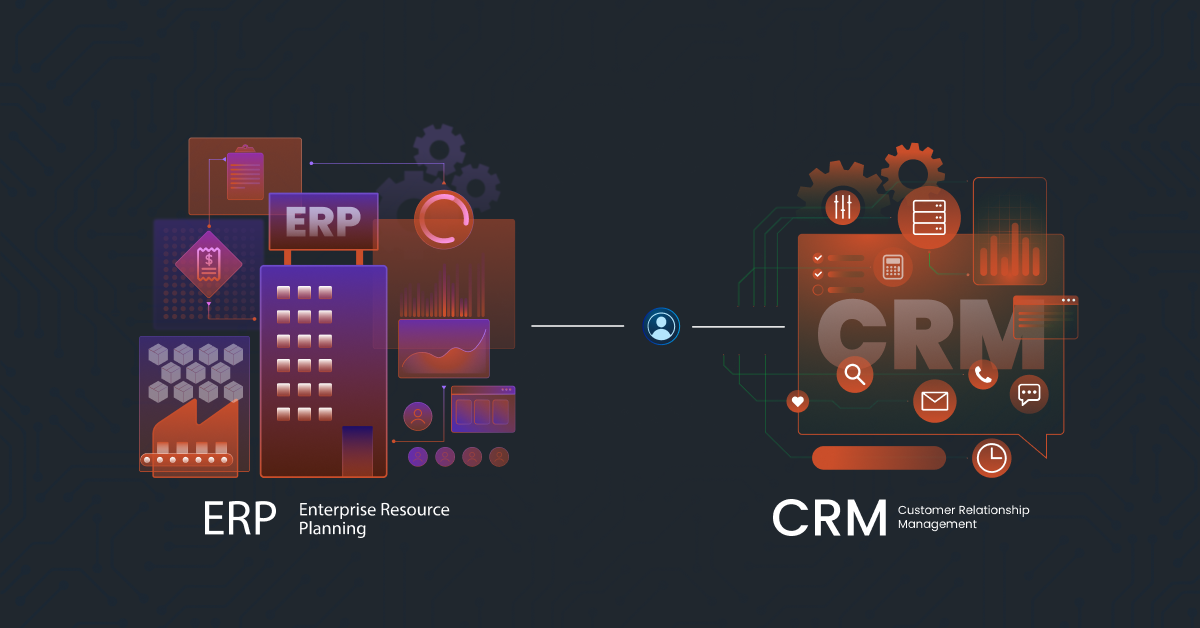

A CRM system can significantly improve your sales performance by streamlining the sales process and empowering your sales team. Features like lead scoring, sales automation, and deal tracking can help you:

- Generate More Leads: Identify and qualify leads more effectively through automated lead capture and scoring.

- Close Deals Faster: Automate repetitive tasks, such as sending follow-up emails and scheduling appointments, to free up your sales team’s time.

- Increase Sales Conversion Rates: Track sales performance, identify bottlenecks, and optimize your sales strategies.

- Improve Sales Forecasting: Gain a clearer picture of your sales pipeline and forecast future revenue with greater accuracy.

3. Increased Efficiency and Productivity

Time is money, especially for small businesses. A CRM system can help you save time and increase productivity by automating tasks, centralizing information, and streamlining workflows. You can:

- Automate Repetitive Tasks: Automate tasks such as data entry, email marketing, and appointment scheduling.

- Centralize Information: Access all customer data in one place, eliminating the need to switch between multiple applications.

- Improve Collaboration: Enable your team to collaborate more effectively by sharing customer information and tracking progress.

- Reduce Errors: Minimize errors by automating data entry and providing a single source of truth for customer information.

4. Data-Driven Decision Making

In today’s data-driven world, informed decisions are crucial for success. A CRM system provides valuable insights into your customers, sales performance, and marketing efforts. You can:

- Track Key Performance Indicators (KPIs): Monitor key metrics such as sales revenue, customer acquisition cost, and customer lifetime value.

- Generate Reports and Analytics: Gain insights into customer behavior, sales trends, and marketing effectiveness.

- Identify Opportunities: Discover new opportunities for growth by analyzing customer data and market trends.

- Optimize Marketing Campaigns: Track the performance of your marketing campaigns and make data-driven adjustments to improve results.

5. Improved Customer Service

Exceptional customer service is a key differentiator for small businesses. A CRM system helps you provide better service by:

- Managing Customer Inquiries: Track and resolve customer inquiries and support tickets efficiently.

- Providing Personalized Support: Access customer information and history to provide personalized support and solutions.

- Improving Response Times: Automate responses to common questions and provide quick and efficient support.

- Gathering Customer Feedback: Collect customer feedback and use it to improve your products and services.

Choosing the Right CRM System for Your Small Business

Selecting the right CRM system is a crucial decision. With a plethora of options available, it’s important to choose a system that aligns with your specific business needs and budget. Here are some factors to consider:

1. Define Your Needs and Goals

Before you start evaluating CRM systems, take the time to identify your specific needs and goals. What problems are you trying to solve? What are your priorities? Consider the following questions:

- What are your key business objectives?

- What are your current challenges in managing customer relationships?

- What features are essential for your business?

- What is your budget?

- Who will be using the CRM system?

2. Evaluate Features and Functionality

Once you have a clear understanding of your needs, you can start evaluating different CRM systems. Look for features that align with your goals, such as:

- Contact Management: The ability to store and manage customer information.

- Sales Automation: Features like lead scoring, deal tracking, and sales pipeline management.

- Marketing Automation: Features like email marketing, social media integration, and lead nurturing.

- Customer Service: Features like support ticket management, knowledge base, and live chat.

- Reporting and Analytics: The ability to track key performance indicators (KPIs) and generate reports.

- Integrations: Compatibility with other tools you use, such as email marketing platforms, accounting software, and social media channels.

3. Consider Scalability and Flexibility

Your CRM system should be able to grow with your business. Choose a system that can scale to accommodate your future needs. Consider the following:

- Scalability: Can the system handle an increasing number of users, contacts, and data?

- Customization: Can the system be customized to meet your specific business requirements?

- Integration: Does the system integrate with other tools and applications you use?

- Mobile Accessibility: Does the system offer mobile access for your team on the go?

4. Assess Pricing and Support

CRM systems come with a variety of pricing models. Consider your budget and choose a system that offers a pricing plan that fits your needs. Also, assess the level of support offered by the vendor. Consider the following:

- Pricing: What is the cost of the system? Does it offer different pricing plans?

- Support: What level of support is offered? Is there online documentation, email support, or phone support?

- Training: Does the vendor offer training and onboarding support?

- Implementation: How easy is the system to implement and set up?

5. Research and Compare Options

Once you have a clear idea of your needs and the features you’re looking for, it’s time to research and compare different CRM systems. Read reviews, compare features, and consider free trials before making a decision. Here are some popular CRM options for small businesses:

- HubSpot CRM: A popular, free CRM with a wide range of features and integrations.

- Zoho CRM: A comprehensive CRM with a variety of features and pricing plans.

- Salesforce Sales Cloud: A powerful CRM with a wide range of features, ideal for growing businesses.

- Pipedrive: A sales-focused CRM designed to help sales teams manage their pipeline.

- Freshsales: A sales CRM with features like built-in phone, email, and chat.

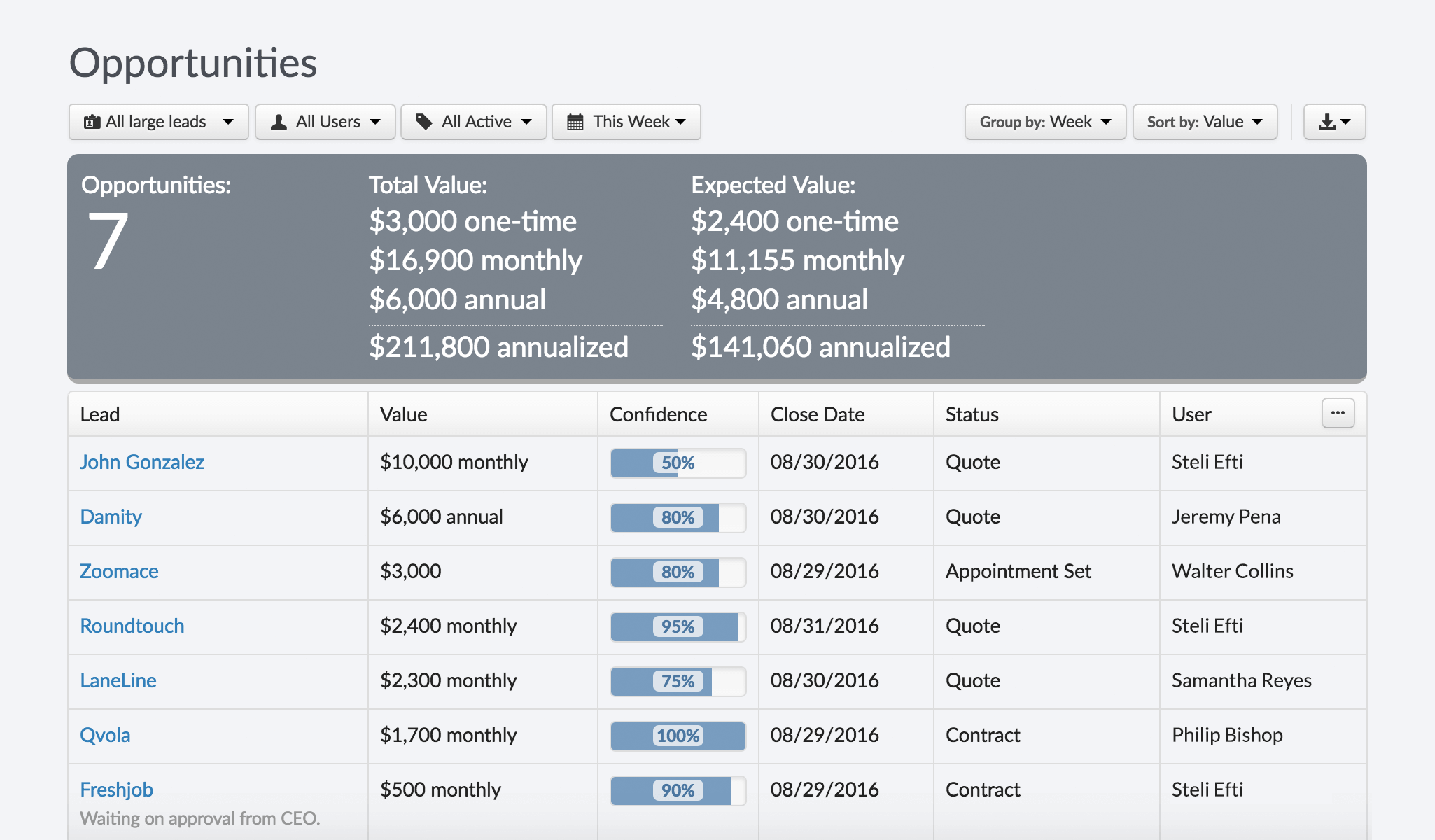

Implementing Your CRM System: A Step-by-Step Guide

Choosing the right CRM is only the first step. Successful implementation is key to realizing the full benefits of your new system. Here’s a step-by-step guide to help you get started:

1. Plan Your Implementation

Before you start implementing your CRM system, take the time to plan your approach. Define your goals, identify key stakeholders, and create a detailed implementation plan. Consider the following:

- Define your goals: What do you want to achieve with your CRM system?

- Identify key stakeholders: Who will be involved in the implementation process?

- Create a timeline: Set realistic deadlines for each stage of the implementation.

- Allocate resources: Determine the resources you’ll need, such as time, budget, and personnel.

- Choose an implementation method: Will you implement the system yourself or hire a consultant?

2. Data Migration

Migrating your existing data to your new CRM system is a crucial step. This involves importing your customer data, sales data, and other relevant information. Take the following steps:

- Clean your data: Remove duplicate records, correct errors, and ensure data accuracy.

- Map your data: Map your existing data fields to the corresponding fields in your CRM system.

- Import your data: Import your data into your CRM system using the import tool or a data migration service.

- Verify your data: Check your data to ensure it has been imported correctly.

3. Customize Your CRM

Customize your CRM system to fit your specific business needs. This may involve:

- Configuring settings: Set up your CRM system to match your business processes.

- Creating custom fields: Add custom fields to capture specific information relevant to your business.

- Setting up workflows: Automate tasks, such as sending follow-up emails and assigning leads.

- Integrating with other tools: Integrate your CRM system with other tools, such as email marketing platforms and accounting software.

4. Train Your Team

Provide your team with adequate training on how to use the CRM system. This will ensure that everyone is comfortable using the system and can take full advantage of its features. Consider the following:

- Develop a training plan: Create a training plan that covers all aspects of the CRM system.

- Provide hands-on training: Provide hands-on training to your team, allowing them to practice using the system.

- Create user guides and documentation: Create user guides and documentation to help your team use the system.

- Offer ongoing support: Offer ongoing support to your team, answering their questions and providing assistance.

5. Monitor and Optimize

Once your CRM system is up and running, monitor its performance and make adjustments as needed. Track key metrics, gather feedback from your team, and optimize your processes. Consider the following:

- Track key metrics: Monitor key metrics, such as sales revenue, customer acquisition cost, and customer satisfaction.

- Gather feedback: Gather feedback from your team on how the system is working.

- Optimize your processes: Identify areas for improvement and optimize your processes accordingly.

- Update your system: Regularly update your CRM system to ensure it remains up-to-date and secure.

Real-World Examples: CRM in Action

To truly grasp the power of CRM, let’s look at some real-world examples of how small businesses are using it to drive growth:

Example 1: Retail Business

A small clothing boutique uses CRM to:

- Track customer purchase history and preferences.

- Send personalized email promotions based on past purchases.

- Offer loyalty programs to reward repeat customers.

- Provide personalized recommendations and styling advice.

Result: Increased customer loyalty, higher average order value, and a boost in sales.

Example 2: Consulting Firm

A consulting firm uses CRM to:

- Manage leads and track their progress through the sales pipeline.

- Schedule meetings and follow-up calls.

- Track project progress and client communication.

- Automate proposals and contracts.

Result: Improved lead conversion rates, increased efficiency, and better client communication.

Example 3: Service-Based Business (e.g., Landscaping)

A landscaping company uses CRM to:

- Manage client information and track service history.

- Schedule appointments and manage job assignments.

- Send automated reminders and invoices.

- Track customer satisfaction and gather feedback.

Result: Improved customer satisfaction, streamlined operations, and increased profitability.

Overcoming the Challenges of CRM Implementation

While the benefits of CRM are undeniable, implementing a CRM system can present some challenges. Being prepared for these challenges can help you ensure a smooth and successful implementation:

1. Resistance to Change

Some employees may resist adopting a new system, especially if they are accustomed to using manual processes. To overcome this, consider the following:

- Communicate the benefits: Clearly explain the benefits of the CRM system to your team.

- Involve your team: Involve your team in the selection and implementation process.

- Provide adequate training: Provide comprehensive training to help your team learn how to use the system.

- Lead by example: Demonstrate the value of the CRM system by using it yourself.

2. Data Migration Issues

Migrating data from your existing systems to the new CRM system can be a complex process. To mitigate these issues:

- Plan ahead: Plan your data migration process carefully.

- Clean your data: Clean your data before migrating it to the new system.

- Test your data: Test your data after migration to ensure its accuracy.

- Consider professional help: Consider hiring a data migration specialist to help you with the process.

3. Integration Challenges

Integrating your CRM system with other tools and applications can be challenging. To ensure smooth integration:

- Choose a system with good integration capabilities: Choose a CRM system that integrates with the other tools and applications you use.

- Plan your integration: Plan your integration process carefully.

- Test your integration: Test your integration to ensure it is working correctly.

- Seek professional help: Consider hiring an integration specialist to help you with the process.

4. Lack of User Adoption

If your team doesn’t use the CRM system, you won’t be able to realize its full benefits. To encourage user adoption:

- Make the system easy to use: Choose a CRM system that is user-friendly and easy to navigate.

- Provide adequate training: Provide comprehensive training to help your team learn how to use the system.

- Offer ongoing support: Offer ongoing support to your team, answering their questions and providing assistance.

- Monitor user adoption: Monitor user adoption and take steps to address any issues.

The Future of CRM for Small Businesses

The landscape of CRM is constantly evolving, with new technologies and features emerging. Here’s what the future holds for CRM in the small business world:

1. Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML are already transforming CRM, and their impact will only grow in the years to come. Expect to see:

- Predictive Analytics: CRM systems that can predict customer behavior and recommend actions.

- Automated Insights: AI-powered tools that analyze customer data and provide actionable insights.

- Intelligent Chatbots: AI-powered chatbots that can handle customer inquiries and provide support.

2. Increased Automation

Automation will continue to play a key role in CRM, streamlining processes and freeing up time for your team. Expect to see:

- More sophisticated workflows: Automate more complex tasks, such as lead nurturing and sales forecasting.

- Integration with more tools: Integrate your CRM system with a wider range of tools and applications.

- Hyper-personalization: Deliver highly personalized experiences to your customers using automated tools.

3. Mobile CRM

Mobile CRM will become even more important as businesses become more mobile. Expect to see:

- Improved mobile apps: CRM systems with more powerful and user-friendly mobile apps.

- Real-time access to data: Access to real-time customer data and insights from anywhere.

- Geolocation features: Features that use geolocation to track customer interactions and provide location-based services.

4. Focus on Customer Experience

Customer experience will continue to be a key differentiator for businesses. CRM systems will play an even greater role in helping businesses deliver exceptional customer experiences. Expect to see:

- More focus on customer journey mapping: CRM systems that help you map and optimize the customer journey.

- Integration with customer feedback tools: CRM systems that integrate with customer feedback tools to gather insights.

- Personalized customer service: CRM systems that enable you to provide highly personalized customer service.

Conclusion: Embracing CRM for Sustainable Growth

In conclusion, CRM is no longer a luxury; it’s a necessity for small businesses striving for sustainable growth. By embracing a CRM system, you can transform your customer relationships, boost your sales performance, increase efficiency, and make data-driven decisions. While implementation may require some effort, the long-term benefits are well worth the investment. By understanding the fundamentals of CRM, choosing the right system, and implementing it effectively, you can position your small business for success in today’s competitive market. So, take the leap, explore the possibilities, and unlock the power of CRM to fuel your business’s growth and achieve your entrepreneurial dreams. The future of your business may very well depend on it.